Capsule handling at a high level

KCP15

The Krämer capsule polisher will elevate, polish and dedust any size of capsule. The rotational spiral brush designed specifically for capsule applications polishes gently and removes excess dust. The perforated housing allows ideal removal of the dust. The device outlet can be fitted with peripherals such as metal detectors, empty capule sorters and diverters.

- Upward conveying range of 800 to 2000 mm

- Dust-tight Tri-Clamp connections

- Available with Ceia, Lock and Safeline metal detectors

- Quiet operation < 68 dB

- Speed continuously adjustable

- Optimal cleaning of capsules with gentle conveying

- Compact design, minimum footprint

- Modular structure (400 mm)

- Easy assembly and disassembly, no tools are needed

- Easy to clean

- Classification: Atex Zone II 2D/- Db 140 °C

Conveying height

800-2000 mm

Available Metall Detectors

Ceia, Lock, Safeline

Easy to use control panel

The KCP10 and KCP15 utilize a simple frequency controller that allows for continuously adjusting the conveying speed. In addition, the power supply cable uses a quick connect plug. The quick connect plug allows for use of preassembled cables with power supply as well as signal wire options for communication to upstream equipment such as capsule fillers.

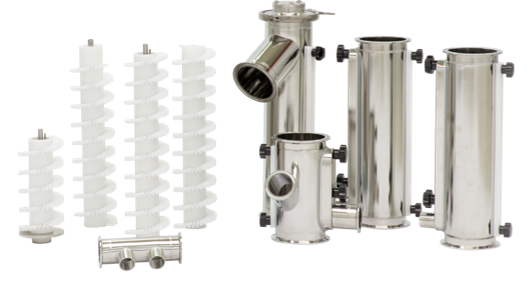

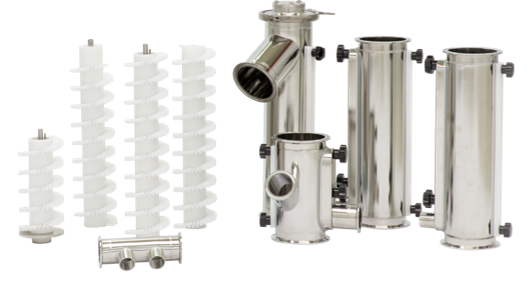

Brush design – an innovative Approach

The rotational spiral brush designed specifically for capsule applications polishes gently and removes excess dust. With our unique stepless design between brush modules, we do minimize product jam and guarantee continuous product conveying. Every single brush module can be marked accordingly in order to keep track of dedicated products.

Krämer DESIGN and drive system

The KCP Series drive features a state of the art geared motor with a special designed shaft seal that prevents dust from entering the drive unit. The special cGMP design allows for easy cleaning and maintenance. Regardless of our conveying height, this unit provides the most economical way of upwards conveying on a minimal footprint, thanks to its compact design as a stand alone or combined unit with metal detector.

Connection ports

With the use of optional inlet adapters, the capsule polisher is easily adjustable to various capsule filler discharge configurations. If an adapter is not being used, a hose can directly be attached to the Tri-Clamp inlet. The inlet can be rotated 360° independent of the outlet. All Krämer capsule polisher feature a 2 inch Tri-Clamp vacuum dust collection port for ease of assembly of a dust collection hose. Various optional hose adaptors are available upon request. The perforated housing allows ideal aspiration of the dust on each module independently.

Ease of assembly and Disassembly

No tools are needed to assemble or disassemble the machine for cleaning. All product contact surfaces are AISI 316L stainless steel. All Krämer machines minimize the number of parts to be cleaned, and keep the weight of each part minimal for ease of handling. This assures quick and effortless cleaning processes.

Containment and ATEX Performance

The KCP10 and KCP15 capsule polishers have been independently tested and certified to meet OEB 3 and OEB 4 containment levels in accordance with ISPE – SMEPAC requirements as well as the EC Machinery Directive 2006/42/EC and Directive 94/9/EC (ATEX-95).

Specifications

Power Supply

110 V, 50/60 Hz - 230V, 50/60 Hz

Peak current

4-2 A

Noise emission (1 m)

< 68 dB(A)

Elevation height

800-1200-1600-2000 mm

Outlet height

930-2130 mm

Inlet height adjustable

Inlet height

503 mm

Total height

1465-2665 mm

Conveying technology

Upward conveying brush

Drive unit technology

Gear motor

Footprint

932-545mm

Product contacting parts

AISI 316L, stylon, PET-G, PUR

Weight

105-150 kg

Compressed air

Ø6/4mm, 50-100 l/min (p=1.5-2 bar)

Air extraction

2" tri-clamp, 100-250m3/h (p=10-20 mbar)

Product inlet

2" tri-clamp

Product outlet

Ø 66 mm

Protection rating drive unit

IP54

Protection rating housing/controller

IP50

Controller

Control with potentiometer

Metaldetector models

Ceia THS/PH21 EE , Lock PH IQ4 , Safeline Tablex 2S

Metaldetector sensitivities

Ceia SS316L=0.50 / FE=0.30 / N-FE=0.35 , Lock SS316L=0.50 / FE=0.30 / N-FE=0.35 , Safeline SS316L=0.50 / FE=0.30 / N-FE=0.40

Processing of tablets (var. forms ) Ø3-35 mm

Processing of mini/micro-tablets Ø1.5-3 mm

Processing of effervescent tablets Ø25-35 mm

Processing of capsules Nr. 4-00

Conveying speed capsule size Nr. 4

300'000 caps/h

Conveying speed capsule size Nr. 3

300'000 caps/h

Conveying speed capsule size Nr. 2

300'000 caps/h

Conveying speed capsule size Nr. 1

300'000 caps/h

Conveying speed capsule size Nr. 0

300'000 caps/h

Conveying speed capsule size Nr. 00

250'000 caps/h

Explosion protection ATEX 94/9/EG

II 2D/- Db 140 °C

OEL Level acc. SMEPAC

OEB 3-4

cGMP compliance

CE compliance

Option sample collection

Option inlet adapter

Option outlet adapter

Option air extraction adapter

Option metal detector test tablet insert device KT2010

Option WIP manual/auto

Option 4 way drain valve system (drain/air exctraction/return)

Option hepa filter

Option empty capsule sorter KCS10

Option jam sensors

Option 2-way diverter manual KV2010 DT/WIP

Option 2-way diverter auto KV2020 DT/WIP

Option 2-12-way diverter auto V40000-V5000 DT/WIP

Option filling level sensors

Option air extraction monitoring

Option validation documentation

Option material certificates